Project Description

Aluminium Can Baler/ Metal Scrap Baler

Recycling steel scraps, metal scraps, aluminum cans and tins are of supreme importance. These Aluminium Can balers are also called can balers or metal balers. They are specially manufactured to compress metal scraps like steel scraps, aluminum scraps, copper scraps etc. into block. The compressing is done without any strapping which means there is no strapping materials cost and smelting cost involved. These aluminum can baler for sale are widely used by recycling centers, steel works and aluminum products plants due to their efficient and proficient working mechanism.

The larger heavy duty metal baler models not only used for compressing aluminum cans but also customized to compress metal leftover, steel shavings, and steel scraps. Furthermore, the optional manual and automatic control systems of the metal baler enable the automation of machine and allow the manual use as well. The choice is users.

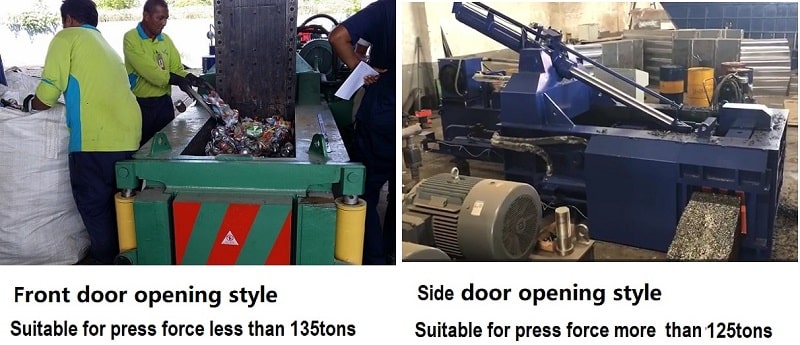

We offer two designs for our heavy-duty models: front bales ejecting out style and side bales ejecting style. The front ejecting style is suitable for press forces less than 135 tons, while the side bales ejecting style is recommended for press forces exceeding 125 tons.

Side ejecting and front ejecting of aluminum can baler

The bale size can be customized according to your specific needs, ranging from 200*200*Hmm to 650*650*Hmm. If you require a smaller bale size, we also offer two styles of small aluminum can balers for your option.

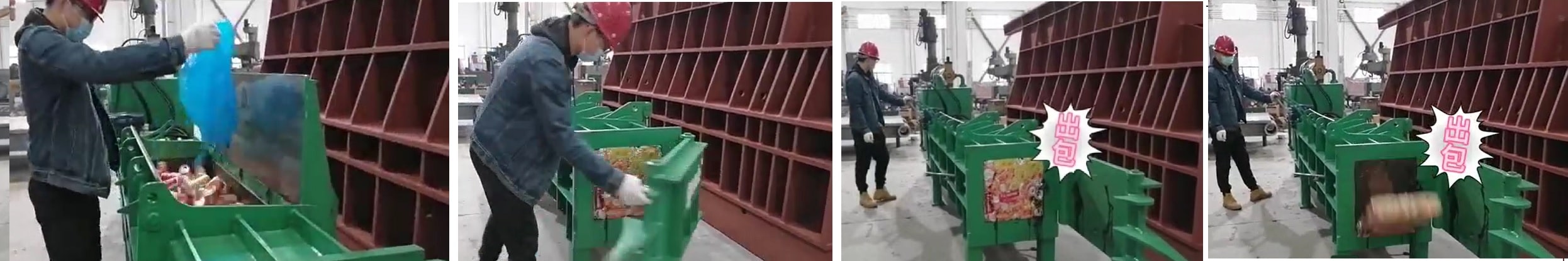

Small Style 1: This mini style can be connected to a conveyor for automatic feeding of aluminum cans or metal scraps into the compressing bin. It features a main compressing cylinder and an ejecting door opening cylinder, making the process simple and efficient.

Mini aluminum can baler

A larger full-automatic aluminum can baler is also available as an option, with bale capacity of up to 60 pieces per hour.

Full automatic aluminium can baler

Small Style 2: In this mini style, aluminum cans or metal scraps are manually fed into the compressing bin. It utilizes a compressing plate cylinder and a main compressing cylinder, and the close-end door is opened manually.

Manual feeding aluminum can baler

If you prefer a vertical baler for processing aluminum cans, we recommend our manual vertical balers – can balers or mini balers. These balers require manual feeding and manual strapping, but they occupy minimal floor space and are cost-effective. Alternatively, we also offer a heavy-duty manual vertical baler – two ram balers, which does not require strapping and has a large press force of over 100 tons.

Simply choose the model that best fits your specific requirements, or share your needs with us so we can customize a machine specifically for you. We are committed to meeting all your baling needs for aluminum cans and other metal scraps. Contact us today to get your machine.

| Technical Parameter for Full automatic aluminu scrap baler (1000M4040) larger or smaller models are available | ||

| Main Cylinder | Size | DIA 220/160mm |

| Pressure | 1000KN | |

| Stroke | 1210mm | |

| Side Cylinder | Size | DIA 220/160mm |

| Pressure | 1000KN | |

| Stroke | 1740mm | |

| Small Door Cylinder | Size | DIA 100/65 |

| Pressure | 100KN | |

| Stroke | 500mm | |

| Compressing Box Size(L*W*H) | 1500*800*400mm | |

| Hopper (L*W*H) | 2200*1200*1500mm | |

| Bale Size (W*H) The bale length is adjustable according to the material feeding volume |

400*400mm | |

| Bale Weight | 30-35kg | |

| Working pressure(Mpa) | 20Mpa | |

| Cycle time | 40s | |

| Capacity | 90 bales/h (about 2.7-3.15tons/h |

|

| Motor | 37KW | |

| Wearing Plate | Hardox-450 | |

| Oil Pump | Pressure | 31.5Mpa |

| Outflow | 180ml/r | |

| Qty | 1pc | |

This Aluminum Can Baler process the following materials:

Cans / tins

Before

After Compressing

Aluminum scrap

Before

After Compressing

Mini can baler/small aluminum scrap baler

Full automatic aluminum can baler

Metal scrap baler

Full automatic aluminum scrap baler

Get A Free Quote For This Baler

According to your special baling requirements, customized baling machines will be provided according to your unique baling needs. Contact us today for your unique baling machines. You will get our reply within 24hours.